These ten best practice tips will help to reduce running costs by making a compressor installation more energy efficient now and for the years to come:

1: Reduce unloaded running hours

Air demand in an industrial compressed air system typically fluctuates. Using these patterns to reduce unloaded running hours is a first step to optimising energy efficiency. Compressor controllers offer user-friendly ways to reduce unloaded running hours.

If there are multiple compressors, then they should have been set up to do this automatically. But if there is no central controller, then the compressor pressure bands should have been set up in a cascade method, and the on-board controllers will stop the machines if they are not needed when the compressed air target pressure is achieved. Most on-board machine controllers have the function of programmable start/stop timers. If compressors are left running unloaded after working hours, they still use as much as 25% of the energy consumed at full load. What’s more, if there are leaks in the system, the compressors may switch to loaded running occasionally, consuming even more energy.

The shorter the production time, the more that can be saved by switching off compressors instead of letting them run unloaded. If production is reduced but not stopped, a possibility would be to isolate areas of the factory that are not currently being used

2: Eliminate air leaks

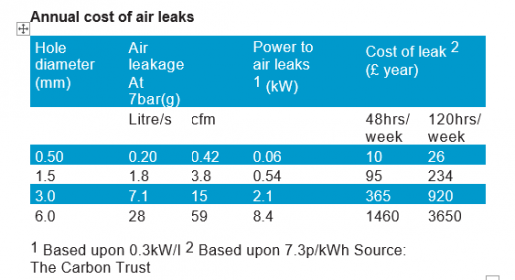

Leakages are the most significant source of energy waste in older compressed air systems, with a leakage point as small as 3mm costing an estimated £980/week in wasted energy. It is estimated that up to 20% of total compressed air consumption may be lost through leaks.

If there are people still working on-site that have some spare time, we recommend they take the opportunity to detect the leaks in the system. For example, they could run the air compressor with no production to check for leaks. Fixing air leaks will lead to money savings immediately.

3: Reduce the pressure band

As a rule of thumb for most compressors, a reduction of 1 bar in pressure (14.5 psi) could lead to a 7% saving in electricity consumption. The pressure settings of the compressor should be adjusted until the lowest pressure can be reached, and the pressure band reduced without affecting the applications.

For centralised systems using multiple compressors, by using a central controller, the network can be set to run within a narrow pressure band which ensures that the compressed air network matches the precise needs. The controller can also allow manufacturers to manually or automatically create two different pressure bands to optimise energy use within different periods, drastically reducing energy costs at low-use times. Also, lowering the system pressure reduces the impact of leaks. A 1 bar pressure reduction decreases the effect of air leaks by 13%.

4: Turn compression heat into useful energy with heat recovery

One area that offers manufacturers a significant opportunity for savings is to recover the waste heat from air compressors. Without energy recovery, this heat is lost into the atmosphere via the cooling system and radiation. The amount of electrical energy that can be recovered depends on the size of the compressor and the running hours. Typical recoveries are between 70-94%. It is estimated that90% of all industrial air compressors used in the UK could be equipped with heat recovery systems.

Recovering heat from compressed air reduces the need for purchasing energy, for example, to heat water or using exhausted cooling air for space heating. It is this reduction that results in lower operating costs and CO2 emissions, also reducing carbon footprint.

To illustrate the vast untapped potential of compressed air heat recovery, it is calculated that compressor heat recovery technology could save 1.99% of the total industrial electricity consumption in the UK. If that statistic isn’t compelling enough, it is the equivalent of removing the emissions from 913,000 diesel/ petrol cars per year or recovering the energy required to power 1.544 million households’ electricity consumption per year

*Calculations are based on total industrial electricity consumption in the UK and an average of 10% of industrial electricity consumption being used by compressors

*Approximately 70% of energy is recoverable from oil-injected screw compressors, and up to 94% from oil-free water-cooled screw compressors.

5: Ensure the correct size of compressor is installed

Choosing the wrong size air compressor for a facility can lead to problems with production and or increased costs due to wasted energy. When selecting a compressor, manufacturers should ask themselves these questions:

What is the application?

How much air flow does their facility/workshop use?

What is the minimum pressure needed within the facility? Do they need clean/dry air (use of dryer and filters)?

How many hours per year does their compressor operate?

How many shifts do they run per day? Is there fluctuation in flow demand between shifts (if so, a VSD compressor could be a good option and offer significant savings)?

Are there any plans for future expansion?

Once they have answered those questions, they should select the compressor not based solely on the initial purchase price but based on the one with the lowest total lifecycle costs. Since 70% of the total LCC of a compressor is spent on energy, the right choice will add up to a significantly reduced bottom line for the factory.

6: Ensure the correct type of compressor technology is installed

Many applications in the food and beverage, electronics, automotive, textile and pharmaceutical industries will require oil-free air to guarantee product integrity and quality (often specified as Class 0). Oil-free compressed air technology will help to avoid expensive filter replacements, cut the cost of oil condensate treatment and reduce energy loss from pressure drop in filters and, in food & beverage applications, the use of expensive food-grade lubricants.

There are some extremely energy-efficient oil-free compressors on the market. For example, a ZR 90-160 VSD+ oil-free rotary screw air compressors offer up to 10% more output and 15% lower energy consumption compared to previous models. They even have the optional benefit of having an integrated, guaranteed -40ºC pressure dew-point dryer that offers almost zero energy consumption.

If the application is very large-scale, a centrifugal compressor should be considered, since these offer unbeatable energy efficiency in process air or bulk air applications presenting a flat load, or when providing a baseline flow in mixed installations with VSD screw compressors.

7: Consider a Variable Speed Drive (VSD) compressor Most production processes require different levels of demand in different periods, which may mean that the compressor is running off-load or idle (not producing any compressed air) for long periods of time. Considerable savings can be made if a variable speed drive unit can replace a fixed speed compressor, as it only produces compressed air as and when required. This also minimises off-load running of the compressor, which is known to waste energy. A VSD compressor saves an average 35% energy and a VSD+ unit can save as much as 50% compared to a fixed speed unit, even at full load.

As a fixed speed compressor has a fixed amount of motor starts an hour, the compressor runs off-load for a set time which limits the number of motor starts to ensure overheating of the motor does not occur. As a VSD unit ramps up and down in a controlled fashion, the maximum number of starts and stops per hour may be increased, and it also avoids peaks in current when starting.

8: Get an air audit

Compressed air consumption should never rely on guess work. To find out how to increase efficiency, the system needs an assessment or an audit.

Cost is usually the most significant difference between the two, as a simple compressed air assessment can be a complementary walk-the-line visual inspection. In contrast, an in-depth audit based on data logging can cost £1000s and take weeks or months to complete, depending on the size of the facility and the desired outcome. Companies may be reluctant to perform a full air audit due to costs associated with such services, but the outcomes can far outweigh the initial investment. It is essential to understand that the benefits from assessments and audits do not end only with lowering energy costs, but also improving the overall efficiency of the production, therefore positively affecting the bottom line. Not every facility needs to do a full compressed air audit or air scan, as sometimes a simple walk-the- line assessment can satisfy the needs and result in substantial energy savings. Switching or updating a compressed air installation to the latest technology can reduce energy consumption by up to a quarter. If there is an old or inefficient compressor, the cost to replace it with a new compressor is often less than the current running costs. A modern air compressor with the latest controllers and energy-efficient motors will contribute to the bottom line from day one, meaning a short payback time.

A complete compressor replacement is not the only route, however. Exchange programmes offer the possibility of replacing major components of a compressor with new, more efficient parts. For example, upgrading a compressor with the latest type of electronic controller will allow manufacturers to take advantage of the most advanced compressor control management, reduced unloaded running and higher efficiency. And if an old, lower efficiency motor is replaced with a new, high-efficiency one, energy savings are guaranteed.

9: Reap the benefits of modern compressed air equipment Air compressors are long term investments that will play a significant part in a business for years to come. The average factory changes air compressors every 7-10 years, meaning that the initial capital expenditure is only a fraction of how much a compressor will cost in total. 70% or more of an air compressor’s lifecycle cost will come down to its energy usage.

10: Don’t forget the impact of regular maintenance The best way to ensure compressed air availability is by investing in regular preventative maintenance, which will sustain the efficiency that is gained by purchasing a new compressor or improve the performance of an older unit.

If manufacturers prefer to purchase spare parts only and perform maintenance in-house, they can sign up to a planned maintenance programme at pre-determined intervals from the manufacturer or approved distributor or choose a total responsibility package that covers breakdowns and leaves no room for surprises, the main thing to remember is that reduced compressor performance is not inevitable as the machine gets older. Regular servicing, using OEM genuine parts, will improve equipment uptime and energy efficiency: the opposite could lead to more downtime, increased energy consumption and potentially a costly breakdown.

Lastly, gather some data. For example, most Atlas Copco compressors come fitted with a Smartlink data box which can provide live information on the compressor status, and can also map the compressor’s operating hours, with off-load / on-load hours and, of course, warning information.

www.atlascopco.co.uk/compressors

https://twitter.com/AtlasCopcoUKIRE/

https://www.linkedin.com/company/atlas-copco/

https://www.facebook.com/AtlasCopcoUKIRE/