LM Wind Power, an international designer and manufacturer of wind turbine blades, has recently turned to EcoCooling for an evaporative cooling solution. Although the company’s manufacturing staff at its Hampshire facility are protected against the chemicals involved in the manufacturing process, there was a requirement to provide fresher air for the team working nearby in offices that were hot in summer and cold in winter.

Air conditioning units had proved expensive and inefficient, so the company turned to EcoCooling for a solution. Approved installers, Vent-Tech, installed an evaporative cooling unit around the people working onsite with minimal disruption, at a fraction of the cost of a traditional AC system.

The EcoCooler unit was adjacently positioned and ducted into a heat recovery unit on the roof to keep the offices at a steady 21°C all-year-round while using very little energy/carbon.

EcoCooling fresh air and adiabatic/evaporative cooling systems are installed in over 2000 facilities across the UK, providing fresh cool air to people and processes without the need for refrigeration. According to the company, its customers have seen productivity in sites improve by up to 30% after installation of its EcoCooling equipment.

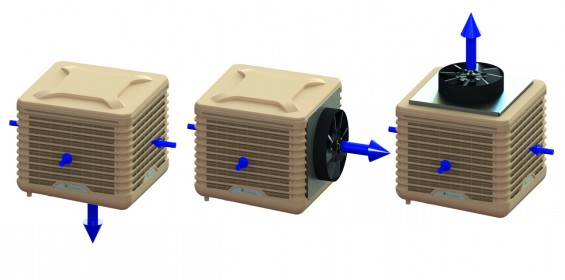

During colder weather the EcoCooling system works in ventilation mode, outside air is used to cool the building while hot air is extracted out. On hotter days, the natural process of evaporation is used in EcoCoolers to cool incoming air. By evaporating water into the air, temperatures are reduced without the need for mechanical refrigeration, making evaporative cooling an economically viable and green option for large building and process cooling.

Andrew Edge, project manager Materials and Processes, LM Wind Power, commented: “We are able to achieve a constant comfortable temperature within our offices, plus the fresh air being pumped in from outside means the environment is generally much more pleasant to work in. We are delighted with the end result.”

One ECP EcoCooler can provide cooling for 15m diameter circle of floor space - doors and windows being open will not affect performance. While mobile coolers offer a flexible alternative to a fixed installation and can be used as trials.

****************

Energy Consumption:

Running costs for a single unit ECP external EcoCooler Small based on an average airflow of 12,000 m3/hr are:

Utility Usage and Cost per Hour

Electrical Consumption £0.120

Water Consumption (average) £0.012

Total Cost per Hour £0.132

Total cost per 168-hour continuous working week £22.18

For further information please visit: www.ecocooling.co.uk