Keeping a close eye on the condition of critical equipment is fundamental in any industrial facility. When critical bearings fail, it almost always leads to unplanned downtime and interrupted production process, costing companies thousands in production loses.

Critical equipment: bleach decker in a pulp and paper plant

Usually, in pulp and paper plants we will find a wash floor or wash area, where the paper comes through to be thoroughly cleaned / bleached. That job is done by a machine called a bleach decker, which is considered a critical and fundamental piece of equipment for production operations.

In this particular plant, which has a predictive maintenance programme in place, it was decided to invest in online monitoring for these machines. The maintenance team wants to be alerted as soon as anything unusual is happening with the equipment in order to prevent any failures that would lead to a stop in production. This machine has four bearings, of about 120 cm diameter, rotating at 3RPM.

To enable online monitoring and early failure detection, ultrasonic sensors are being used on the machines’ bearings. These are UE Systems Remote Access Sensors, which are permanently installed on the bearings and constantly collect decibel readings and sound recordings. All this data is then sent to a central processing unit called the 4Cast. This unit is connected to the Internet and will alert the maintenance team (e-mail and SMS alerts) when certain decibel levels are reached.

Failure detection

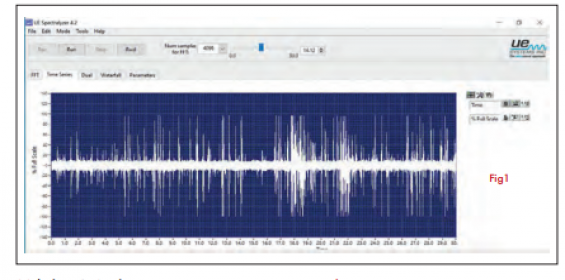

Everything seemed to be fine with the bleach decker at this pulp and paper facility, as the machine was working as expected. However, the 4Cast, an ultrasonic online monitoring system, received an unusual decibel reading from one of the ultrasonic sensors. The NDE (non-drive-end) bearing of this bleach decker was registering 17dB when, normally, a bearing rotating at such slow speeds like 3RPM should simply show a 0dB reading.

This triggered the system to immediately alert the maintenance team.

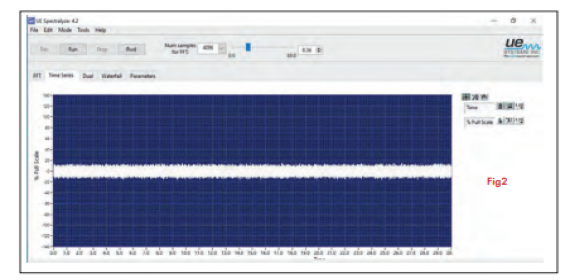

When an alarm level is reached, the 4Cast will also take a sound recording from the bearing for further analysis. This is especially useful in slow speed bearings, where the sound spectrum can tell us a lot about what’s going on with the asset. In this case, and even though the machine was apparently working as expected, the sound file spectrum showed a very different story.

The signs of impact are obvious. Also, metal fragments were found in the shaft, plus spalling, with some pitting, and slight abrasion were present in the outer race.

Conclusion By detecting the issue at an early stage, the maintenance team was able to replace the bearing during scheduled downtime and without disrupting the production process. We can imagine the consequences if the issue was not detected at this stage and the bearing was allowed to continue operating: the metal fragments would certainly affect the motor shaft, which would then also need to be replaced; and the facility would have to face unplanned downtime. In such a situation we could be looking at a loss of around 250K GBP. By using the proper technology, with the proper maintenance procedures in place, the team was able to identify and solve the issue before it became a major problem. This case study illustrates how powerful ultrasound technology can be, especially when used in sensors connected to the network to provide truly online and permanent monitoring solutions.

https://twitter.com/UE_Systems

https://www.linkedin.com/company/ue-systems/