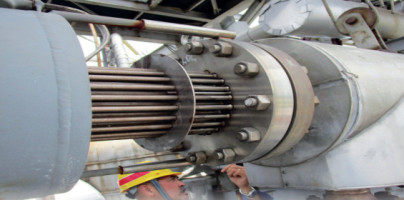

Thermal solutions are a part of almost every industry, from chip manufacturing and medical devices to oil and gas operations. What these diverse industries have in common is a need to design simple, yet responsive systems that can monitor and maintain the precise application of heat. However, this need means that engineers must contend with various complexities.

Any device or process with a heater needs some degree of thermal control, with some devices or processes needing more precise control than others. That precision is traditionally achieved by adding sensors and controllers to heaters. The more precision needed, the more complex the control apparatus and the wiring becomes. adaptive thermal solutions (ATS), which combines sensing, heating and control technologies, represent a different and more innovative approach to controlling thermal performance for complex systems. However, adding the complexity is not always an option, which is where challenges present themselves.

Complex systems in small spaces

A surface that needs to be heated to within a certain temperature range requires not only several heating elements, but also sensors that can detect the temperature of the surface at various points. Those sensors then deliver that feedback to a controller that then responds by adjusting the power sent to the heaters. If the temperature of the surface fluctuates, the sensors and controller should be able to respond in tandem to maintain the desirable temperature range.

Traditionally, the approach to getting such fine control of the heating surface has been to increase the zone count, which requires the addition of independent sensors, wires and controllers. As the system scales, the complexity grows, but the overall space in which this needs to happen does not. In many manufacturing scenarios, precise control is needed in a confined space, and additional wiring and equipment is not feasible.

Control system challenges

Manufacturers may experience disconnection between their control systems. Different banks of sensors at different points in a process are often connected to separate controllers, which might not be networked in such a way that their activity can be coordinated easily, which results in unresponsive systems.

The above challenge often results in adding an element of unpredictability to the system. The added complexity of additional sensors and controllers will, for some applications, either compromise adaptability or prevent the system from achieving desired thermal uniformity. These, in turn, lead to excess waste and variable material quality.

Unlocking these challenges

Precision and tunability of a thermal system is traditionally achieved by adding sensors and controllers to the system. But there are plenty of applications where this is not a viable option, including semiconductor manufacturing, analytical devices, and home medical devices. ATS makes possible a greater degree of control in systems where piling on more components is simply not an option.

Every application is unique, and some can take advantage of many ATS technologies at once while others might use just one. In semiconductor manufacturing, deposition pedestal heaters must reach certain temperatures during the chipmaking process and temperature uniformity is critical to quality control. The pedestal itself allows little room for extra wires. With high TCR materials and multiloop control and sensing, individual heaters can be made into sensors, and the number of heating zones can be more than doubled. These zones can be independently controlled, in real time, adjusting heater output to achieve a more uniform surface temperature.

Furthermore, existing medical and analytical equipment often must meet new agency requirements, like safety specifications for allowed temperatures. Having heaters that can sense their own temperature, when then adjusts power levels via power conversion, helps to keep temperatures within safe limits.

The beauty of ATS is that it is not one solution, but a suite of solutions that can be tailored to specific engineering challenges. Unlocking the benefits of this technology requires a deep understanding of the product or process in question, including the thermal and power requirements of the system.

* Brittany Phillips, Engineering Manager at industrial electric heating element manufacturer Watlow

https://www.linkedin.com/company/watlow/